|

ENAMEL - (formerly lard) - is a glassy coating consisting of a mixture of powdered minerals, such as: sand, chalk, clay and fluxes, fired at temperatures from 800 - 9000C. The first mention of enammeling meets in the second century BC in Egypt. Enammaling art was also already known in ancient China, Persia and Byzantium. By mid-fifteenth century enammeling knowledge was closely guarded by the masters of this art. In Western Europe, enamel industry spread in the eighteenth century. The task is to protect the enamel surface of the metal from corrosion and harsh chemicals. Enamel is used in food, pharmaceutical and chemical industry in particular. Enamel is smooth, shiny and tight. It is resistant to all organic and inorganic acids and their salts (with the exception of hydrofluoric acid and phosphoric acid at a concentration of more than 85%). The coating is heat resistant and thermal shock resistant, has high UV resistance, mechanical strength and abrasion resistance. Enamel is ecologically clean. |

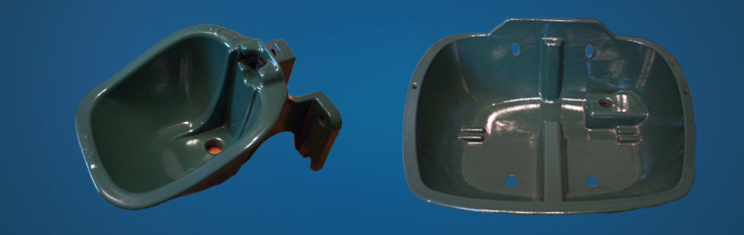

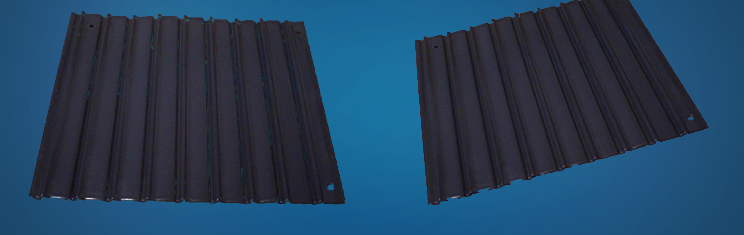

1980 - The idea of building enammeling factory. 1983 - Research of enammeling the steel. 1985 - Indroducing enammeling silencer by the way of Ferguson licence. 1992 - Implementing enammeling the cast. 1994 - Introduction to the production of all types of cast-iron enameling valves, heads and hydrant pipes. 1995 - Receiving awards announced by Izba Rzemieślnicza w Katowicach "Firma z Jakością". 2002 - implementation of quality management system ISO 9001:2000. 2004 - Start of production for livestock watering enamelling and boilers. 2006 - purchase of a new chamber for blasting metal surfaces. 2008 - electrostatic enamelling line launch, according to Nordson technology. 2009 - use of ultrasonic cleaning methods. |

|

|